We make customized medications for our patients, both humans and animals, with care each time. We use our knowledge of drugs, pharmaceutical sciences, and calculations on each formula.

Quality starts with our selection of ingredients-the active pharmaceutical ingredient (API) as well as inactive ingredients such as the base (cream) or suspension vehicle. We use FDA Registered suppliers that provide a certificate of analysis of their ingredients to assure us that the ingredient is what it says it is and that it meets the required specifications.

While compounding, our technicians use a bar coding system to ensure the correct ingredients are chosen. They use an analytical balance to weigh ingredients that is integrated into our software that ensures the correct ingredient weights. But still how do you know what you make it correct?

We have a rigorous set of standard operating procedures in which compounding staff are trained on. We are USP <795> and <797> compliant. USP, the United States Pharmacopeia, sets quality standards for medications, dietary supplements and food ingredients worldwide. We follow a formulation record to very closely while we are compounding a preparation so that it is compounded the exact same way each time. As a part of our quality assurance program, each formula is evaluated upon completion to make sure it meets our quality control process. For example, when batch of capsules is completed, we check the weight variance. We weigh a percentage of the capsule batch to make sure they fall within the calculated weight range. This, along with the ingredient verifications and ingredients weights, provides us assurance that the capsules are compounded correctly. We periodically go one step further and actually send out a portion of a batch to an outside laboratory to be tested. This testing validates that our formula and our compounding technician. We do this third party potency testing for each technician on all of the dosage forms they compound over the course of a year.

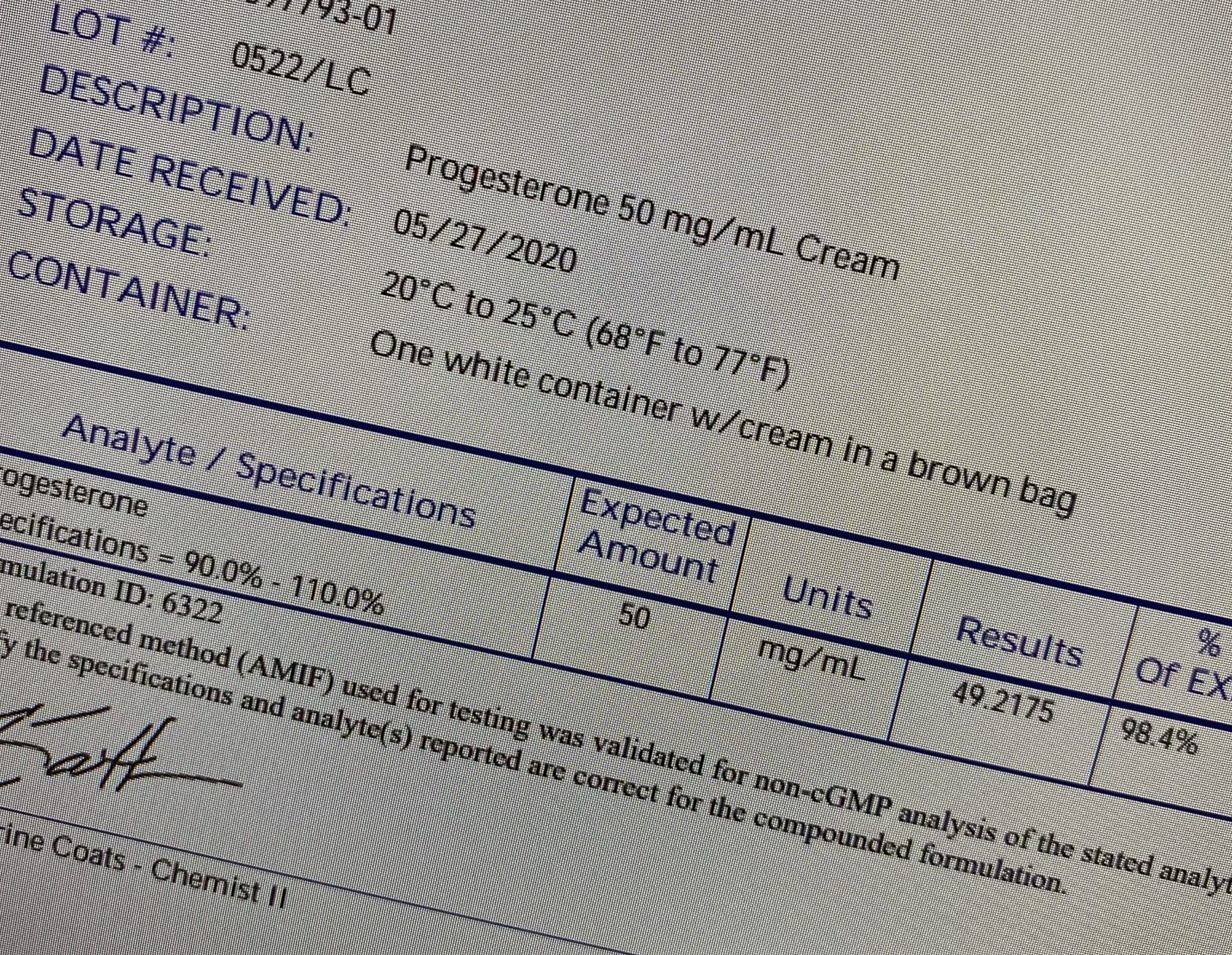

In this picture to the right, you can see that we recently compounded a progesterone 50mg/ml cream. The potency test shows the actually potency of this preparation is 49.2mg/ml or 98.4% of the expected potency. This is well within the allowable USP standard which is 90-110%.

We have taken it one step further for our practice as well. We are proud to be a PCAB-Accredited Compounding Pharmacy. The Pharmacy Compounding Accreditation Board (PCAB) is an accreditation through Accreditation Commission for Healthcare (ACHC) that assures compliance with the highest quality standards and industry guidelines. Achieving compliance involves an extensive onsite survey and annual verification to ensure compliance with the non-sterile and sterile pharmacy compounding process defined by USP <795> and USP <797>.

So now you know a little of what goes on behind the scenes when we make a compound. If you have more questions, give us a call.